SPEEDFAM INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SPEEDFAM INDIA P.LTD.

Double Side Machines

FEATURES

The key to the quality, speed and versatility of SPEEDFAM Double-sided Machine involves a principle known as the 4-way Motion. Utility of the 4-way Motion reduces machining time, surpassing the 2-way and 3-way Double sided machines. Here is how 4-way motion is achieved.

Direction of rotation of the lower and upper plates in relation to the carriers (1 and 2)

Rotational of the carrier in (3)

Axial spin motion of the carrier about the Center of lower and upper plates (4)

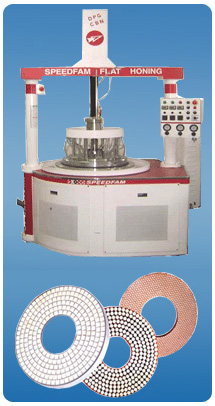

Flat Honing Machines

Flat Honing Machines Systems Technology provides rapid stock removal and precision flat surface machining capability for processing a wide range of hard surfaced materials using either Diamond Pellet or CBN Pellet Plates.

Flat Honing Machining Systems are designed for Efficient Control On Rz, Eco Friendly Fine Honed Sludge and High Stock Removal Rate @ Low CPP.

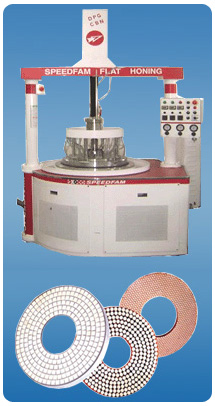

Fine Grinding Machines

Fine Grinding Machines Systems Technology provides rapid stock removal and precision flat surface machining capability for processing a wide range of hard surfaced materials using either Diamond Pellet or CBN Pellet Plates.

Fine Grinding Machines Systems are designed for Efficient Control On Rz, Eco Friendly Fine Honed Sludge and High Stock Removal Rate @ Low CPP.

Fine Grinding Machines is equipped with distinctive features like High Pressure Pneumatic System which ensures precise pressure application for optimum stock removal and increased productivity.

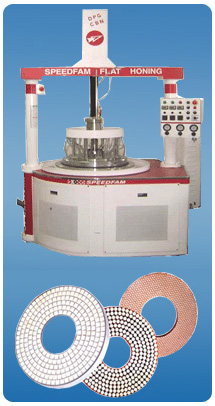

Precision Grinding Machines

Precision Grinding Machines Systems Technology provides rapid stock removal and precision flat surface machining capability for processing a wide range of hard surfaced materials using either Diamond Pellet or CBN Pellet Plates.

Precision Grinding Machines Systems are designed for Efficient Control On Rz, Eco Friendly Fine Honed Sludge and High Stock Removal Rate @ Low CPP.

Able Top Sweeper Arm Machines

Table top sweeper arm machine armpositioned to process one Seal at a time to a very high degree of Flatness & Surface Finish. The Specially Graded Lap Plate with re-circulating Slurry and Sweeper Arm swiveling at tandom achieves efficient cutting properties during the Lapping Process while attaining high degree of flatness & surface finish. Lapping Machine can be conveniently converted to Polishing Machine for polishing operation on the same machine. Typical applications for this machine are mechanical seals etc

Single Side Machines

Description / Specification of Single Side Machines

We are involved in offering a wide range of Single Side Machines to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Single Side Machines. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Table Top Sweeper Arm Machines

Table top sweeper arm machine armpositioned to process one Seal at a time to a very high degree of Flatness & Surface Finish. The Specially Graded Lap Plate with re-circulating Slurry and Sweeper Arm swiveling at tandom achieves efficient cutting properties during the Lapping Process while attaining high degree of flatness & surface finish. Lapping Machine can be conveniently converted to Polishing Machine for polishing operation on the same machine. Typical applications for this machine are mechanical seals etc

Table Top Machines

WORKING PRINCIPLE

Lap/polish plates revolves at low RPM.

The conditioning rings located in position on the machine plate also rotate freely.

The work pieces are kept freely inside conditioning rings with the surface to be lapped mating the Lap Plate.

The sharp abrasive particles which are continuously fed on the machine plate get impregnated in the Lap plate and cut the material from the surface of the work piece and creates replica of the plates flatness on to the same.

These Machines are typically suited for R&D work.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.